DENIMEveryones Choice

Infrastructure

We have the capacity to manufacture 2.5 million meters per month.

Following machineries are installed and well maintained to get the desired production:

- Slasher machine / Rope dyeing

- Warping machine

- Ball Warping

Tsudukoma Airjet Looms [model number: 9200i] specially for 230 cm

Besides that we have installed the following finishing machines to get well furnished products.

Products

From street gazers to chief executives, from children to aged citizens, from travelling to chilling evening wear, when it comes to comfort, denim wear is the first preference. Denim is not only comfort wear but also a style code. Denim is a fabric that is never out of fashion. These unique features of denim leads to increase in demand. As well as with upcoming technology, there are amazing varieties available in Denims.

We make fabrics weighing from 4oz to 14.5oz. The customized production as per requirement, makes our customer stand ahead of all. The products are categorized depending of different parameter. Following are the major categories produced on daily basis.

RANGE

Wider Width Fabric

We can manufacture wider width fabric with weaving capacity of 230cm. As well as the finished fabric will be upto 72 inch.

Stretchable Fabric With Lycra

Stretchable fabric with lycra is also available. It is also known as bubble gum denim. It contains upto 35% to 50% lycra as well as it is stretchable.

WEAVE

4/1 Satin

2/1 Twill

3/1 Twill

Knitted

Dobby

shades

Indigo blue

Sulphur Black

Charcoal Black

Indigo Bottoms Sulphur Top

Sulphur Top Indigo Bottoms

blends

Now a days denims are available in different blends. We manufacture

Polyester Cotton

100% Cotton

Tencel

Our tencel fabric are smooth to skin, soft to touch and luxurious in shine and flow. Majorly it consists of 60% cotton and 40% tencel rayon.

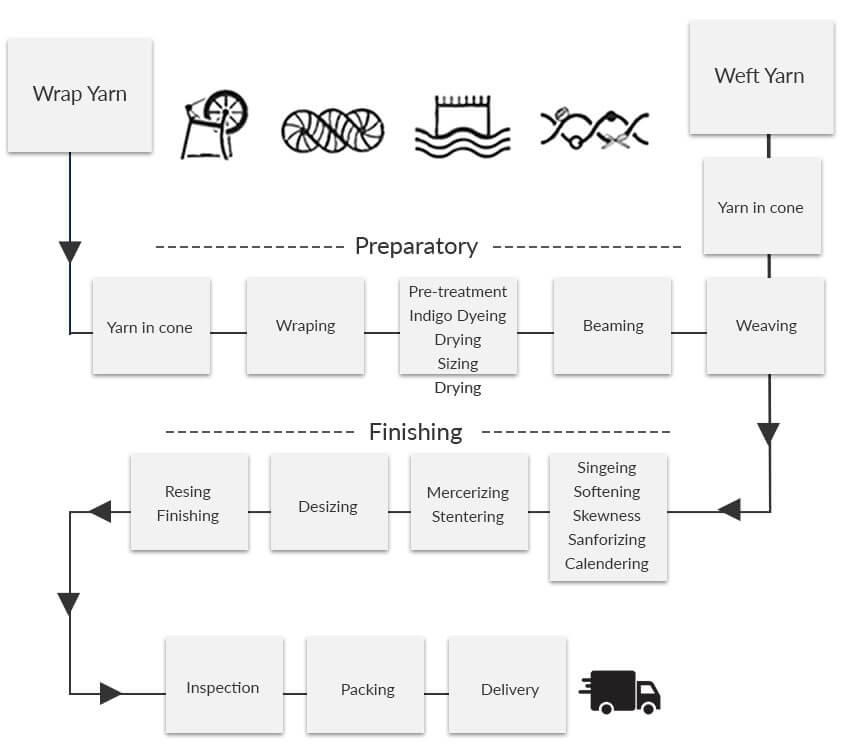

Denim Manufacturing process

Although its not rocket science process but still, maintaining international quality standards at minute levels makes a lot of difference. It basically requires refined knowledge and years of on hand experience to derive. Thanks to our talented R&D team for same.

The Yarn comes from our inhouse manufacturing unit. The selection is done based on several pre defined parameters such as staple length, mirconaire, color range, and the best products are selected for getting desired output.

Certifications

We get our production lots certified by Internationally authorized labs stating that our production lots match all the standards framed for exports.

Associations

We are currently proud members of Texprocil